THE INNOVATIVE AND SAFE PROCESS FOR MAKING AUTOLOGOUS SERUM EYE DROPS

Serum and other blood components (e.g. platelet lysate or PRP) have emerged in the form of eye drops as a highly effective therapeutic option with impressive prospects of success for the severe forms of the indication "dry eye".

The production of serum eye drops is usually time-consuming, labour-intensive and costly. To simplify this process, the idea was implemented to produce the drops safely, quickly and effectively outside a clean room in a closed system. As a result, the current ®ATS type systems are available to manufacturers.

These products have been able to establish themselves very successfully internationally in recent years. It has been shown in practice that for some patients applicators with smaller volumes are indicated.

For the production and preparation of the serum to be filled, e.g. for dilution, we have also configured ®taking systems with different bag sizes as well as other ®supplies (e.g. adapters for sterile filtration).

A description outlining the entire process of manufacturing serum eye drops can be found in the ®download area.

In order to optimise the filling process of eye drops with ATS , special ®elders for automation are available to the user./p>

Application examples

Blood collection system for serum eye drops: Triple bags 1 x 500 ml, 2 x 300 ml

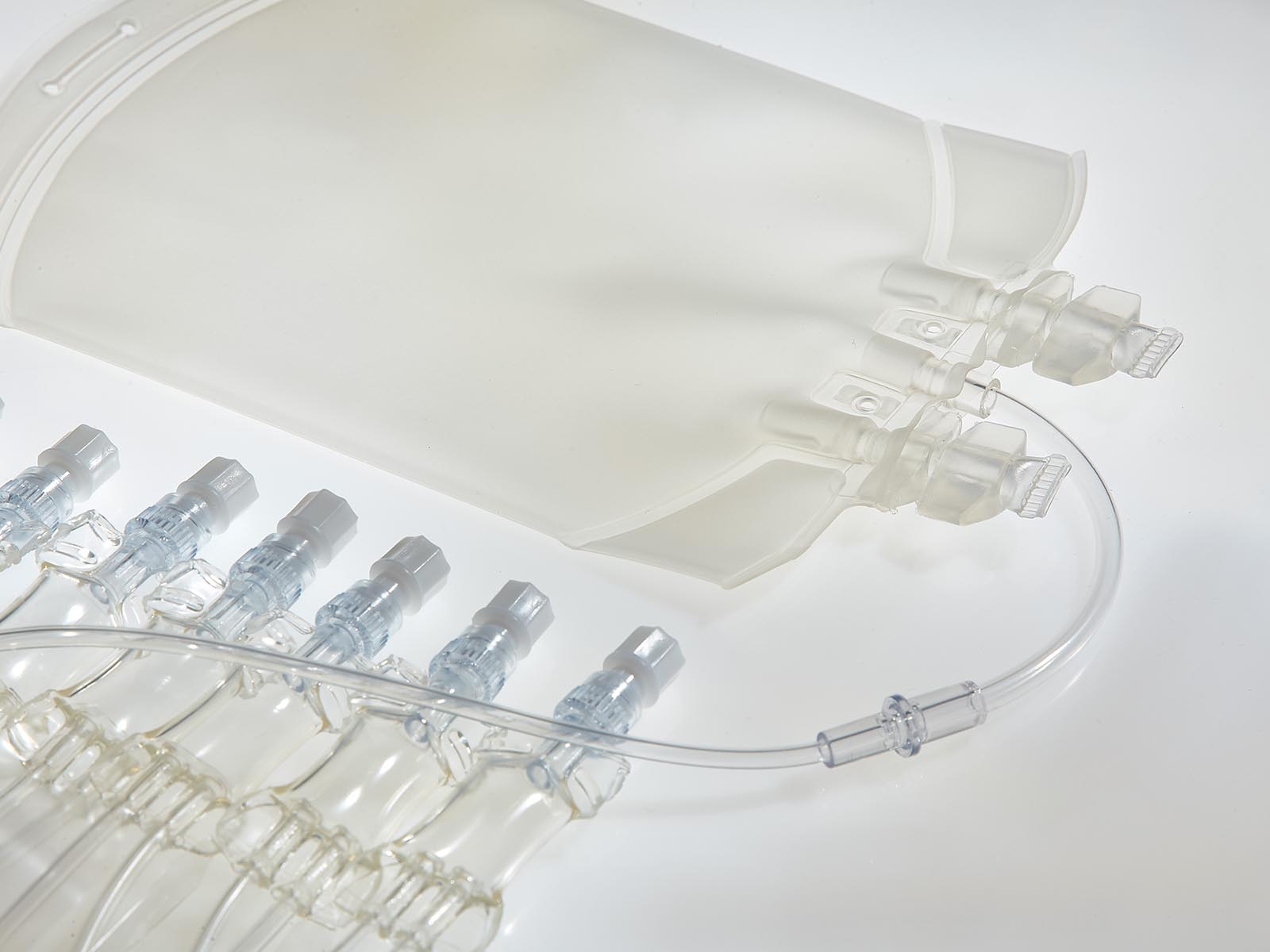

Eye drop system, 12 application receptacles, 1 transfer bag 300 ml

Eye drop system, 36 application receptacles, 1 transfer bag 300 ml

Filling device that accommodates 12 or 36 application receptacles

- Packaging for 10 applications receptacles - Packaging for 30 applications receptacles